Accurate building estimates begin with a detailed scope. The clearer your project definition, the more reliable your budget will be. Vague ideas produce fuzzy numbers and costly surprises. This guide walks through defining scope, organizing costs, gathering local prices, accounting for soft costs and contingency, and assembling a defensible final estimate.

Invalid Date NaN, NaN (Today) — last updated January 5, 2026 (27d ago)

Construction Cost Estimating Guide

Step-by-step process to define scope, price materials and labor, include soft costs and contingency, and produce a defensible construction estimate.

← Back to blogConstruction Cost Estimating Guide

Summary: Step-by-step guide to estimate materials, labor, permits, soft costs, and contingency so you can build a defensible construction budget.

Introduction

Accurate building estimates begin with a detailed scope. The clearer your project definition, the more reliable your budget will be. Vague ideas produce fuzzy numbers and costly surprises. This guide walks through defining scope, organizing costs, gathering local prices, accounting for soft costs and contingency, and assembling a defensible final estimate.

Laying the Groundwork for an Accurate Estimate

Before you price anything, translate your vision into a concrete, actionable plan. Estimating without a defined scope is like trying to build a puzzle with missing pieces — you’ll end up frustrated and over budget.

There’s a big difference between saying you want “a three‑bedroom house” and specifying a “2,500 sq ft, single‑story home with 9‑foot ceilings, Level 4 drywall finish, Andersen 400 Series windows, and engineered hardwood floors.” The first is a dream; the second is a starting point for a real estimate.

From Vague Ideas to Quantifiable Details

Budgets are built on specifics. Defining scope means asking the right questions and writing down the answers. Small decisions — fixtures, finishes, insulation levels — add up quickly. When details are glossed over, assumptions fill the gaps and change orders follow.

Break your vision into measurable parts and get granular in these areas:

- Site work: excavation, grading, utility connections, soil testing

- Foundation & structure: slab, crawl space, or full basement; framing material — wood or steel

- Exterior finishes: siding, roofing, windows, doors — brand and model where possible

- Interior finishes: insulation, drywall level, flooring, paint, trim

- Mechanical systems: HVAC type, plumbing fixtures, electrical needs and special circuits

The time you invest in defining scope is the best investment in your project’s success. It sets expectations, reduces misunderstandings, and becomes the checklist for every dollar you spend.

Breaking Down Your Project Into Key Cost Categories

With scope defined, organize the project into distinct cost buckets. This turns a vague idea into a structured plan and helps you track where money is going.

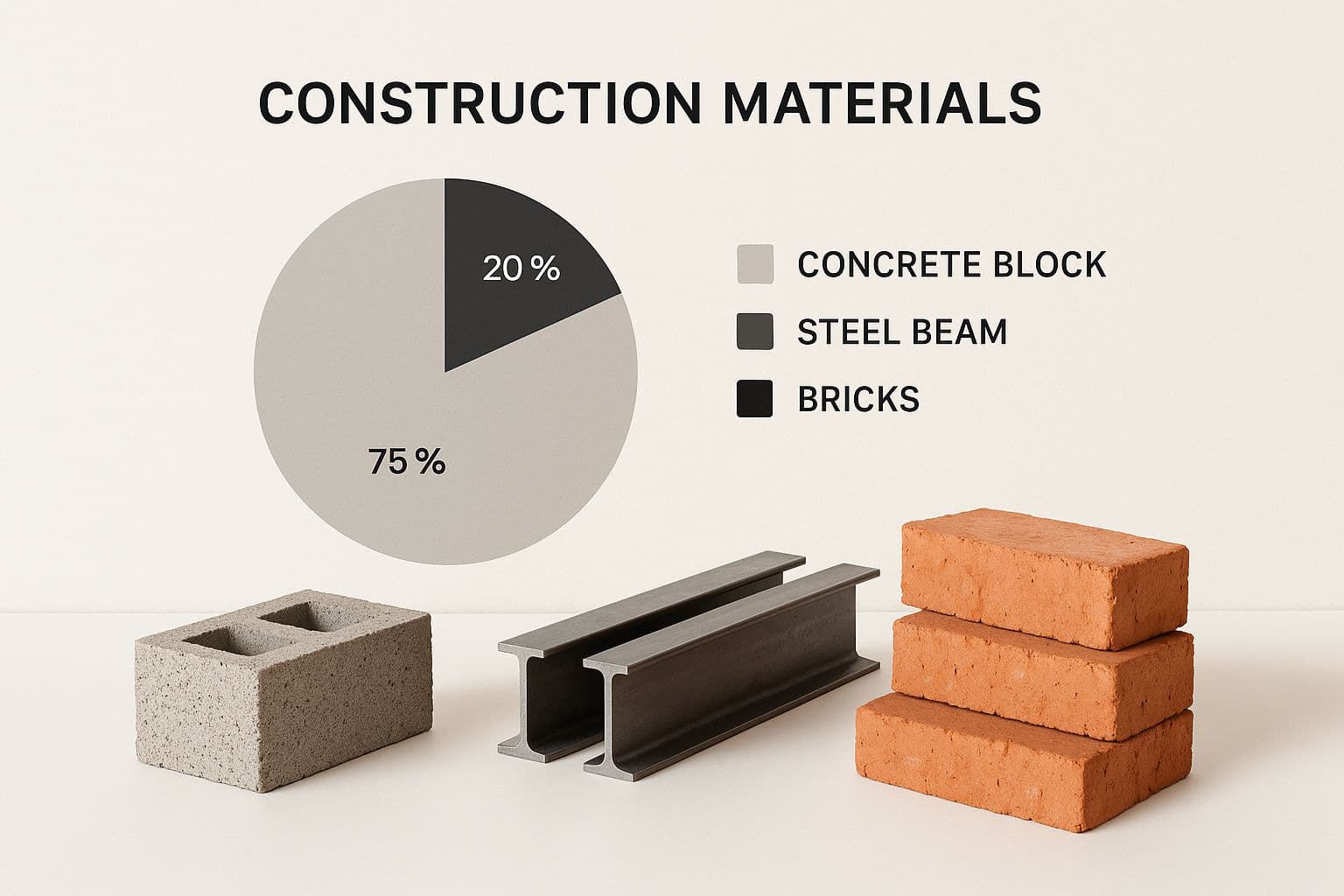

Seeing essential elements visualized makes it obvious how critical it is to accurately estimate quantity and price for each material.

The Big Five Cost Buckets

Most building costs fall into five categories. Understanding each is fundamental to calculating building costs accurately:

- Materials: include lumber, concrete, fasteners, adhesives, wiring, plumbing fixtures, and small items. A detailed material takeoff is essential.

- Labor: wages for every worker. Compare hiring individual subcontractors versus a general contractor. Research local rates for electricians, plumbers, and carpenters.

- Equipment: rentals or purchases — excavators, scaffolding, saws — plus delivery and fuel.

- Permits and fees: local permit costs and inspection fees vary by project value and location.

- Professional services: architects, engineers, surveyors, and designers — soft costs that matter.

For data-driven baselines, try the Construction Material Cost Predictor and the Square Footage Cost Estimator. To ballpark design fees, see the Architectural Design Fee Estimator.

Typical Building Cost Breakdown by Percentage

| Cost Category | Typical Percentage of Total Budget | Key Components to Consider |

|---|---|---|

| Foundation | 10%–15% | Excavation, concrete, rebar, waterproofing |

| Framing | 15%–20% | Lumber, trusses, sheathing, labor |

| Exterior Finishes | 15%–20% | Siding, roofing, windows, doors |

| Major Systems | 10%–15% | HVAC, plumbing, electrical wiring |

| Interior Finishes | 25%–35% | Drywall, flooring, paint, cabinets, fixtures |

| Site Work / Other | 5%–10% | Landscaping, driveways, permits, fees |

These are rules of thumb — material choices and complexity will shift percentages.

Navigating Fluctuating Material and Labor Costs

Costs aren’t static. Recent years saw large swings in lumber, steel, and other commodities alongside labor shortages. Organize your budget into clear categories so you can spot where spikes hurt and make smarter tradeoffs.

Benchmarking by square foot provides a useful high‑level check. Start with the Square Footage Cost Estimator for a quick baseline, then refine with local quotes.

Getting Real-World Costs for Materials and Labor

This is where your estimate meets reality. National averages can be misleading — local prices and labor rates matter. A 2x4 in rural Texas costs different than in downtown San Francisco. Accuracy requires local, up‑to‑date pricing.

Nailing Down Your Material Prices

Never assume. Commodity prices can change fast. Get multiple quotes and confirm delivery and lead times.

- Call at least three local suppliers for big‑ticket items

- Ask about volume discounts or contractor accounts

- Confirm delivery fees and timing

Use the Construction Material Cost Predictor to create a data‑driven baseline for cross‑checking quotes.

Gauging the Local Labor Market

Labor is complex: skill, speed, and availability affect cost. A low hourly rate from an inexperienced crew can cost more in rework.

- Talk to local contractors and subs about typical rates

- Calculate burdened rates that include payroll taxes, workers’ comp, and benefits — these can add 25–50%1

- Check trade associations, like local Home Builders Associations, for standard pay scales

Don’t just estimate cost — estimate value. An experienced crew with higher rates can save money overall by working faster and making fewer mistakes.

Accounting for Soft Costs and Unforeseen Events

Soft costs — professional fees and administrative expenses — can add 15–30% to your total2. Forgetting them is a classic budget killer.

Demystifying Essential Soft Costs

Soft costs include:

- Architectural and design fees: blueprints and documents — complex designs cost more

- Engineering fees: structural, mechanical, electrical, and civil reviews

- Permit and inspection fees: multiple fees tied to project value and inspections

- Insurance: builder’s risk and general liability during construction

- Legal fees: contract review and zoning advice when needed

To ballpark design costs, use the Architectural Design Fee Estimator.

The Non‑Negotiable Contingency Fund

A contingency fund of 10–20% is essential. Surprises are inevitable. Contingency is the shock absorber that keeps your project on track. I’ve seen projects saved by a 15% contingency that covered unforeseen site issues. Without contingency, a surprise can derail the entire build.

Global cost differences matter too — labor rates, taxes, and import duties can make cost‑per‑foot figures unusable across regions. For international work, consult global construction benchmarks and local experts.

By accounting for soft costs and building in contingency, you turn a hopeful guess into a resilient plan.

Assembling Your Final, Comprehensive Estimate

You’ve defined scope, gathered local prices, and accounted for soft costs and contingency. Now combine everything into a clear, defensible estimate.

A simple spreadsheet often works best — line items for every component: material takeoffs, labor hours, subcontractor bids, permits, and contingency. An itemized view ensures nothing gets lost.

Building Your Master Cost Sheet

For a small home addition, include columns for description, quantity, unit cost, and total cost. Examples of line items:

- Excavation & foundation: subcontractor bid or line‑item breakdown

- Framing materials: lumber, sheathing, fasteners listed separately

- Framing labor: estimated hours × burdened labor rate

- Windows & doors: itemize each unit and cost

- Roofing: materials and labor or sub’s bid

Be thorough down to the last can of paint.

Stress‑Testing Your Budget for Reality

Simply totaling numbers isn’t enough. Perform “what if” tests to see how the budget holds up:

- Increase lumber prices by 15% — does your margin survive?

- Add a week of delay due to weather — what’s the labor and equipment cost?

- Replace a subcontractor at a 20% higher rate — can you absorb it?

Use scenario testing to ensure your budget is resilient.

Preparing for Market Fluctuations

Run your budget through scenarios:

- Material price spikes of 10–15%3

- Labor delays that extend schedules and increase costs

- Subcontractor changes that raise rates suddenly

Homeowners can start with the Square Footage Cost Estimator for a baseline, then take that to a professional for a detailed review.

At MicroEstimates, we build tools that put you in control. Use the Construction Material Cost Predictor and the Square Footage Cost Estimator to get started and refine your estimates.

Frequently Asked Questions

What are the first steps to get an accurate building estimate?

Start by defining scope in measurable terms: square footage, finishes, brands, and mechanical systems. Create a detailed takeoff and collect local quotes.

How much should I set aside for soft costs and contingency?

Plan for soft costs of roughly 15–30% and a contingency of 10–20% depending on project complexity and risk.2

How do I protect my budget against material and labor swings?

Build clear cost buckets, get multiple local quotes, and run scenario tests that model price spikes and schedule delays. Use local tools like the Construction Material Cost Predictor and the Square Footage Cost Estimator for baselines.

Quick Q&A — Common Concerns

How do I start if I only have a rough idea?

Begin by defining measurable project parameters: square footage, finishes, and basic systems. Then create a material takeoff and get at least three local supplier quotes.

What size contingency should I use for a renovation?

For typical renovations, 10–15% is common. Increase to 15–20% for projects with unknown site conditions or complex work.

What’s the best way to handle sudden material price spikes?

Build scenario tests into your estimate and negotiate fixed‑price or short‑term pricing where possible. Keep a contingency to cover short‑term volatility.

Bottomline Q&A — Three Quick Answers

How detailed should my scope be before estimating?

Be as specific as possible: exact square footage, finish levels, brands, and mechanical systems. The more detail, the fewer assumptions.

How many supplier or subcontractor quotes should I get?

Aim for at least three competitive quotes for major trades and materials to validate prices and lead times.

When should I hire a professional estimator?

Hire a pro when the project is large, complex, or when you need a defensible bid for financing or bidding — otherwise use the tools and a thorough takeoff.

Additional Concise Q&A Sections

Estimate Basics

Q: What’s the single most important step before estimating? A: Define scope in measurable terms: sizes, finishes, brands, and systems.

Q: What tool helps check a high‑level budget? A: Use the Square Footage Cost Estimator for a quick baseline.

Protecting Your Budget

Q: How do I reduce the risk of cost overruns? A: Get multiple local quotes, add soft costs and a contingency fund (10–20%), and run scenario tests.

Q: Should I lock prices for major materials? A: Where possible, negotiate fixed‑price purchases or short‑term pricing for large orders.

Hiring Help

Q: When is it worth hiring an estimator? A: Hire a pro for large, complex, or financed projects that require a defensible bid.

Q: How do I evaluate subcontractor bids? A: Compare scope, exclusions, lead times, and references — don’t just pick the lowest price.

Ready to Build Your Own Tools for Free?

Join hundreds of businesses already using custom estimation tools to increase profits and win more clients